The TED Blog posted an interesting interview with Catarina Mota on open hardware. She talks about how she came to be involved with open hardware, why it’s a good thing for us be in control of our hardware, and why some people still see open source and open hardware as a bad thing. She also talks about hackerspaces and their contributions to the open source and open hardware communities.

Monthly Archives: November 2012

Electronics and Embedded Design Books

Here’s a quick status update on the site. I’ve started revising the old resource pages, beginning with the Books and References page. Most of the books listed were out of print or old editions, so I’ve started replacing them with comparable books that are currently available. The list is pretty short at present, I’d love to get some input on recommended books you’d consider essential for an open hardware designer. Post a comment below and let me know what to add. Some CC or GFDL licensed ebooks would be really nice if anyone knows of any.

Also, I’ve put up a poll to get some input on what sort of Open Hardware project readers are most interested in seeing. This first poll is to find a general direction for a project and once we get enough input, I’ll put up another to narrow down some features. You can find the poll in the right column of page. If you haven’t picked an option yet, please do.

Olimex OLinuXino: Fast and Open

The PCWorld website posted an article about the open hardware Olimex OLinuXino single board computer. The article compares it to the Raspberry Pi, noting that the while Raspberry Pi hypes their board as open hardware, they have not released their CAD files or complete schematics yet and utilize components that are not available in small quantities. Olimex designed the OLinuXino board to address some of these concerns. All CAD files and complete schematics are available and they use an easy to find CPU. They use the Creative Commons Share-Alike license for all hardware and the GNU GPL license for all software associated with the OLinXino. The board uses a faster CPU than the Raspberry Pi and runs Android, debian, and other GNU/Linux distros. They also tout the board as being noise immune and working in industrial environments with a temperature range of -25 C to 85 C. The OLinuXino uses the standard nano-ITX form factor. The board is priced at 45 Euros (about $57). One point where we’d have to say the Raspberry Pi wins is on the name. It’s unclear how to pronounce OLinuXino, which can’t be good from a marketing standpoint.

So what about the actual specifications?

- A13 Cortex A8 processor at 1GHz, 3D Mali400 GPU

- 512 MB RAM

- 6-16VDC input power supply, noise immune design

- 3 + 1 USB hosts, 3 available for users, 1 leads to onboard pinout

- 1 USB OTG which can power the board

- SD-card connector for booting the Linux image

- VGA video output

- LCD signals available on connector so you still can use LCD if you diasble VGA/HDMI

- Audio output

- Microphone input

- RTC PCF8536 on board for real time clock and alarms

- 5 Keys on board for android navigation

- UEXT connector for connecting addtional UEXT modules like Zigbee, Bluetooth, Relays, etc

- GPIO connector with 68/74 pins and these signals:

- 17 for adding NAND flash;

- 22 for connecting LCDs;

- 20+4 including 8 GPIOs which can be input, output, interrupt sources;

- 3x I2C;

- 2x UARTs;

- SDIO2 for connectinf SDcards and modules;

- 5 system pins: +5V, +3.3V, GND, RESET, NMI

- Optional low-cost 7″ LCD with touchscreen

How Open Hardware will Take Over the World

Nathan Seidle of SparkFun gave an interesting talk at TEDxBoulder about the open hardware business model SparkFun has and offers it as a better model than the innovation-stifling models that rely on patents to suppress competition. It’s a great example of a successful business based on copyleft principles, showing that it’s possible to make money while still protecting the user’s freedoms.

Welcome Back to FreeIO.org!

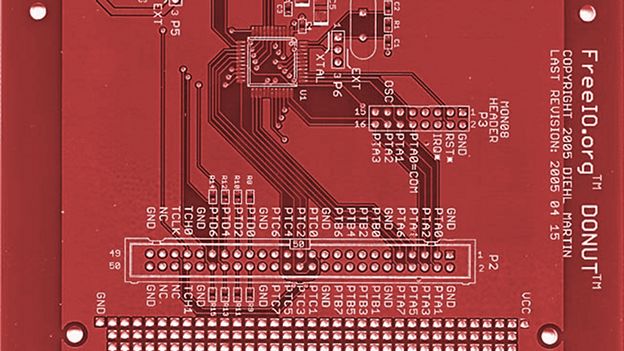

Today marks the official relaunch of FreeIO.org’s website! When Marty founded the site back in March of 2000, he envisioned it as the center of a community interested in hardware freedom. He contributed to that community by developing some of the early free hardware designs and releasing them on this site under the GNU GPL. Marty’s designs were perhaps best know for his unique penchant of naming each board after a different breakfast treat.

Marty passed away on October 25, 2007. But before he lost his battle with pancreatic cancer, Marty passed on all his hardware prototypes, development gear, and this website to me. I’m Steve, better known as Steevithak online. I’ve kept Marty’s original FreeIO.org website intact and online since then, while I pondered what to do with it.

The time has come to get things rolling again and I’m starting with a relaunch of the website. Marty’s free hardware designs are still here and hopefully we’ll find volunteers to work on new hardware projects to add. I’ll also start updating the resource pages to make them more useful again. Meanwhile, I’ve decided to make the site more immediately useful by aggregating all the free hardware and open hardware news, so members of the open hardware community can have one central place to find out what’s going on.

We’re tracking news from the Open Source Hardware User Group, the Open Source Hardware Association, the Open Source Hardware and Design Alliance, and Open Collector. I’m also following blogs for major open source hardware projects like Arduino and Raspberry Pi. To round it out, we’ll have postings of general interest to hardware hackers such as application notes and new product releases from component vendors. If you can think of any cool free/open hardware blogs or news sources we should add, post a comment below. In fact, comments of any sort on how we can make the website more useful to the community are welcome.